The overhead equipment used in ac traction system are flexible to ensure that tension is regulated at different temperature conditions. The bracket assemblies attached to the mast are capable of swivelling along as well as across the track. Standardization of setting distances and the tube lengths of various components becomes necessary.

Assemblies shall allow for the adjustment of contact wire stagger and the equivalent catenary adjustment by 75mm either side of the designed position without changing components.

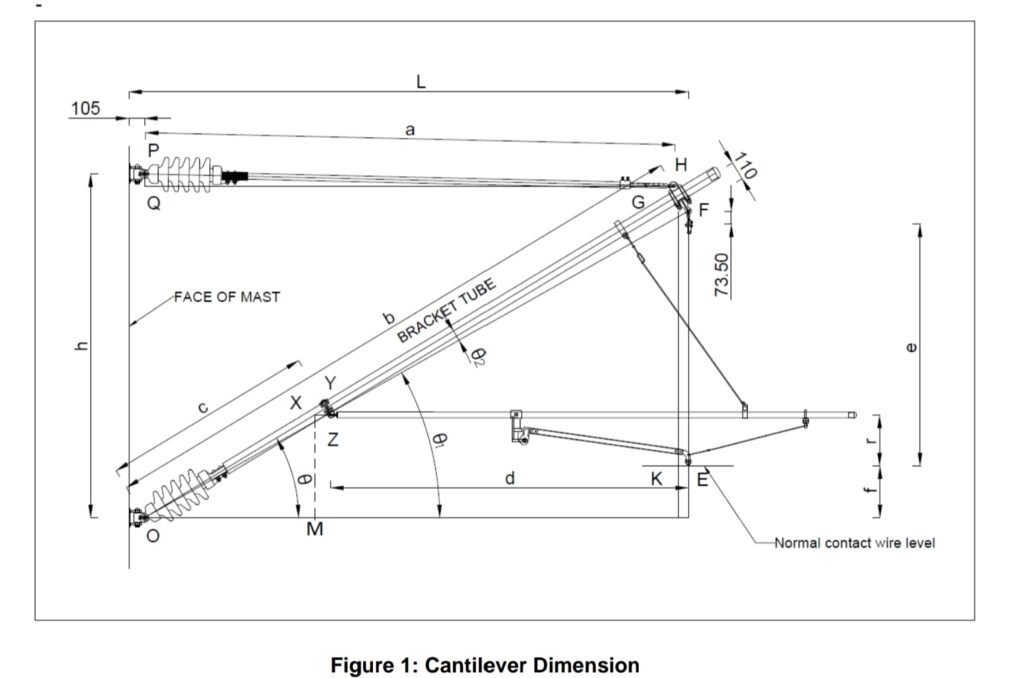

A typical modified IR type cantilever arrangement is shown in the Figure 1 below:

Where,

a = the distance between the mast stay arm fitting (top fitting) and the centre of hook of catenary suspension bracket.

b = the distance between the mast bracket arm fitting (bottom fitting) and the axis of the catenary suspension bracket.

c = the distance from the bottom cap of bracket insulator to the axis of the register arm hook.

d = the horizontal distance between the centre of the hook of the register arm hook and axis of catenary suspension.

e = Encumbrance- the distance between the axis of catenary and contact wires.

f = The distance between contact plane and mast bracket fitting (bottom fitting).

h = Back distance – distance between mast top fitting and bottom fitting.

L = Suspension distance – the horizontal distance from the extreme face of mast stay-arm fitting to the suspension point of catenary.

r =Distance between the contact plane and the register arm axis

θ = angle of inclination of bracket tube with the horizontal = θ1 + θ2

For fixing the dimensions of different parameters of cantilever assembly primarily it is required to fix the position of different clamps as standard values as given below,

The descriptive calculation of a, b, c, & d parameters is shown below:

OF² = OG² + 110² = (e+73.5+f)² + (L-105)²

b² + 110² = (e+f+73.5)² + (L-105)²

Hence,

b = ((L-105)² + (e+f+73.5)² – 1102 ) ½

Where,

Distance from centre of catenary suspension bracket hook to catenary wire axis = 73.5 mm

Distance from edge of mast bracket attachment to vertical axis of mast bracket attachment hook = 105 mm

Distance from axis of bracket tube to centre of catenary suspension bracket hook = 110 mm The following values are considered for example purpose,

e = 1.4 m

f = 300 mm (as standard value as described)

L = 3 m

Hence, b = [(3000-105)² + (1400+300+73.5)² – 1102 )½ = 3393.26 mm = 3.39 m

Accordingly, the styles are defined in cantilever allocation chart to get the dimension and styles.

θ = θ1+θ2

tanθ1 = (e + f + 73.5) / (L-105)

tanθ2 = 110 / b

Then, θ = tan–1[(e+f+73.50) / (L-105)] + tan–1(110/b)

Here in example,

= tan–1[(1400+300+73.5) / (3000-105)] + tan–1(110/3393.26)

= 0.5820 rad

PH² = PQ² + HQ²

PQ = h – (172 cosθ + 73.5 + e + f) = (h – e – f – 172 cosθ – 73.5)

HQ = (L-105 – 172 sinθ)

Where,

Distance from centre eye of adjuster to catenary suspension hook of catenary suspension bracket =

62+110 = 172 mm

Distance from edge of mast stay arm fitting to bottom cap of stay insulator = 105 mm (as shown in

figure)

Therefore, a² = PH² = (h – e – f – 172 cosθ – 73.5)² + (L-105 – 172 sinθ)²

Or, a = [(h – e – f – 172 cosθ – 73.5)² + (L-105 – 172 sinθ)²]½

For the above considered example value of a is calculated and found to be, a = 2801.67 mm = 2.8017m

c = OX + XY + 6.0mm (from above figure)

= MX cosecθ + YZ cotθ + 6.0 mm

= (f + r) cosecθ +52.2 cotθ + 6.0 mm

Where, Distance from bracket tube axis to register arm hook centre = 52.2 mm

Distance from register arm hook central axis to register arm eye piece = 6.0 mm as shown in Figure 2 below:

For the above considered example ‘c’ value is calculated as,

c = (300 + 300) cosec (0.5820) + 52.2 cot (0.5820) + 6.0 mm = 1176.76 mm = 1.177 m

d = L – 105 – OM – XZ

= L – 105 – MX cotθ – YZ cosecθ

= (L – 200) – (f + r) cotθ – 52.2 cosecθ

For the above considered example,

d = (3000-105) – (300 + 300) cot (0.5820) + 52.2 cosec (0.5820) = 1888.32 mm = 1.888 m

Similarly, a, b, c and d parameters for different cantilever assemblies are calculated and tabulated in

this document.

a = Length of stay tube + Insulator length + min/max length of Long adjuster (16 holes)

Where,

Length of Insulator = 491 mm

Min length of Long Stay Adjuster = 146 mm

Max length of Long Stay Adjuster = 356 mm

While erecting the stay tube, to facilitate the adjustment (75mm) mentioned in para no. 2, minimum 3

holes of stay adjuster are kept outside and min 5 holes are kept inside the tube.

NOTE: The total tube length is considered along with the sleeve (55/33.5mm) i.e. the tube is intended

to be inserted up to full length of sleeve.

The stay tube styles based on min/max stay adjuster length for maximum and minimum allowable ‘a’

dimension is tabulated below:

Note: The Stay Tube styles are selected with the difference in length of 200mm as long stay adjuster

has the adjustable length of 210mm. Hence an overlap of 10 mm shall be there in the tube lengths

selected while transiting from one style of stay tube to the next one. In such cases, any of the styles of

stay tubes applicable for the actual tube length requirement may be selected.

b = Length of bracket tube + length of Insulator – 250 mm allowance

Where,

Length of Insulator = 491 mm

Based on the b dimension, Bracket tube styles are is tabulated as below:

Note: The Bracket Tube styles are selected with the difference in length of 50mm for frequently

occurring Suspension distances and the difference in style length is variable for rarely occurring

suspension distances.

The detailed register arm drawing with the steady arm and anti-wind stay is shown in figure 5,

d = (Length of Registration Tube) + (Length of Register Arm Eye Piece) – (horizontal length of anti-wind

stay from contact wire axis to center of eye clip for anti-wind stay) – (half-length of eye clip for anti-wind

stay) – (200 mm allowance)

Where,

Length of Register Arm Eye Piece = 52 mm (Dwg no. 2422-2(S1))

Horizontal length of anti-wind stay from contact wire axis to

center of eye clip for anti-wind stay = 627mm

Half-length of eye clip for anti-wind stay = 15 mm (Dwg No. 2504(S))

d = (Length of Registration Tube) + (Length of Register Arm Eye Piece) – (horizontal length of steady

arm from contact wire axis to axis of steady arm hook) – (Drop bracket length from steady arm hook

axis to edge of drop bracket) – (200 mm allowance)

Where,

Length of Register Arm Eye Piece = 52 mm (Dwg no. 2422-2(S1))

Horizontal length of steady arm from contact wire axis to

axis of steady arm hook = 940 mm for BFB steady arm & 1150 mm for Bent steady arm

Drop bracket length from steady arm hook axis to edge of drop bracket = 75 mm for 25 mm

drop bracket assembly

Based on above, the register tube style defined with difference of 200mm for less frequently occurring

suspension distance and 100 mm for the more frequently occurring suspension distance is tabulated

as below:

Note: The Registration Tube styles are selected with the difference in length of 100mm for frequently

occurring Suspension distances and the difference in style length is 200mm for rarely occurring

suspension distances.